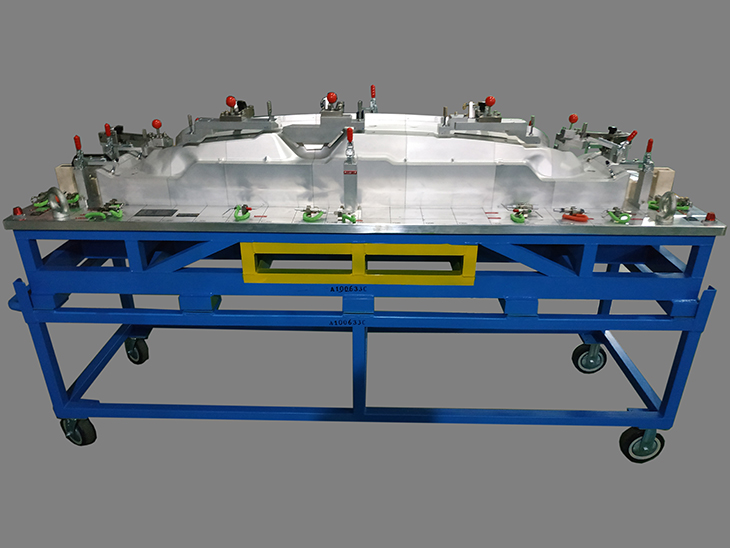

TTM19496 Common measuring bracket checking fixture has high measurement accuracy, no fear of deformation, low maintenance cost and good convenience. Key product characteristic inspection, characteristic line inspection, function hole inspection, area detection which is prone to deformation in assembly process, for automobile assembly and production function matching inspection. In the production process of automotive parts, on-line inspection of automotive parts is realized, which ensures the rapid judgment of the quality status of automotive parts in production, ensures the safety and processing speed of automotive assembly, and improves the quality of automotive parts.

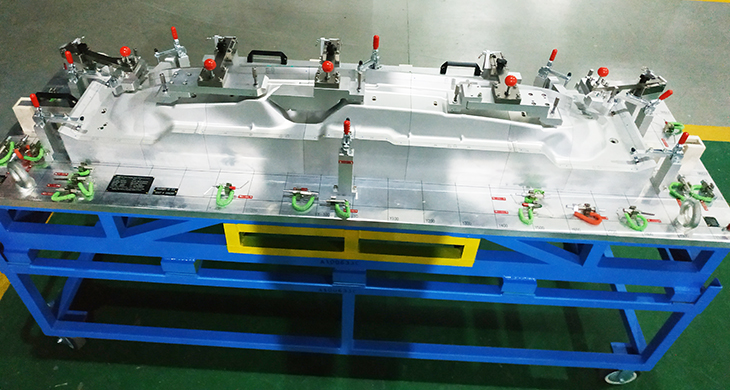

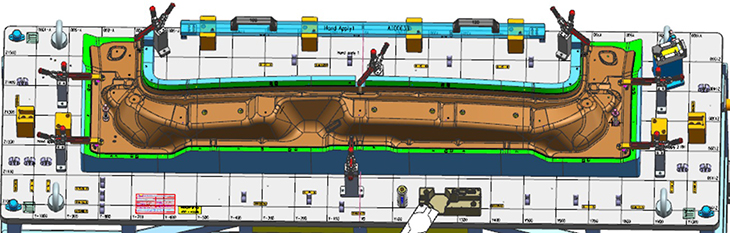

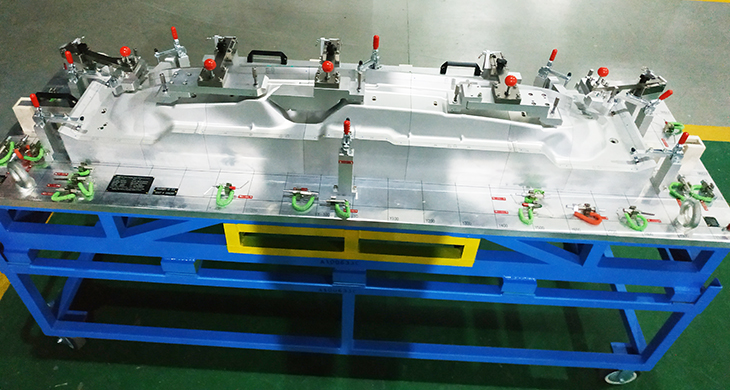

Gage Instructions

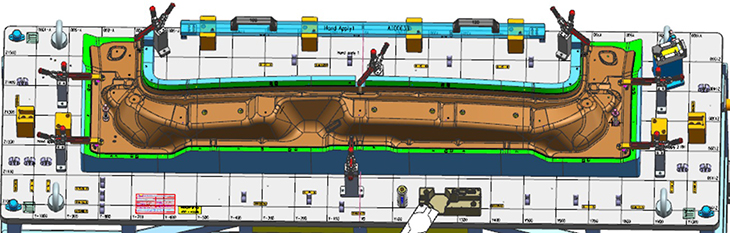

1.Load part on to net pads that are labeled A1, A2, A3 ,A4, A5, A6, D1, D2.(Nets are located in the areas that are circled)

2.Make sure that the part is fully seated on the Datum -B- fixed pin(Datum -B- circled in pictures)

3.Use Datum C Pin labeled "C" to position the part

4.Clamp part in the order shown in the picture